HHWE member Huisman has announced the award of a contract from Denmark-based BMS Heavy Cranes for the delivery of a 3,000mt Ringer Crane, with an option for a second unit.

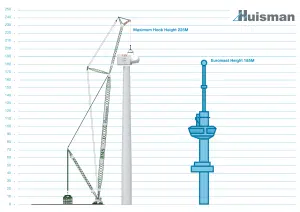

The crane setup has been optimised for operations in the wind industry. With the capability to lift components of 1,200mt at heights of up to 225m, and heavy structures of 3000mt at reduced height, the crane will ready BMS for installation of the next generation of wind turbines on and offshore and on floating foundations. The crane is also well suited to operations in other industries. The fully electrically driven crane helps reduce emissions and improves operational accuracy and energy efficiency ensuring its suitability for use in the renewable energy industry.

Huisman is known for delivering the world’s largest cranes, characterised by lightweight, robust designs and reliable support throughout the lifecycle. The company attributes its success to building long-term relationships with top tier clients, an approach that it says has enabled every step in its capability development.

Delivery of the crane is scheduled for the second half of 2023. Morten Kammer, CEO at BMS Heavy Cranes: “We look forward to the ongoing cooperation with Huisman in the delivery of this crane. This asset represents a major step forward for BMS. With the capability to lift the world’s largest turbines onshore we will be able to play an increasingly important role in the development of renewable, net-zero energy industries.”

David Roodenburg, CEO at Huisman: “We are passionate about designing large cranes and are grateful to BMS for the opportunity and their trust. We can’t wait to see this mega crane in real life. We are happy to once again be applying our experience in a project that aligns with our vision of accelerating the growth of renewable energy production.”

Features & benefits of the Huisman Ringer Crane:

▪ A fully electrically driven system, resulting in high positioning accuracy, efficient energy use, reduced maintenance and higher reliability.

▪ Modular ring system, allowing for a full 360° ring being used, or a portion of it – depending on specific site layouts

▪ Easy breakdown in road transportable pieces enables easy relocation of the crane

▪ A dedicated boom setup, thus ensuring a lightweight and stiff design.

▪ Upending of the crane can be done without the use of assistant cranes

▪ Very low ground bearing pressure

▪ Operable in higher winds than traditional cranes.